Diagnosing and repairing batteries is critical to maintaining their health and ensuring optimal performance over their entire lifecycle. Proper diagnostics helps identify and address potential issues early and guides a maintenance plan to support long-term functionality.

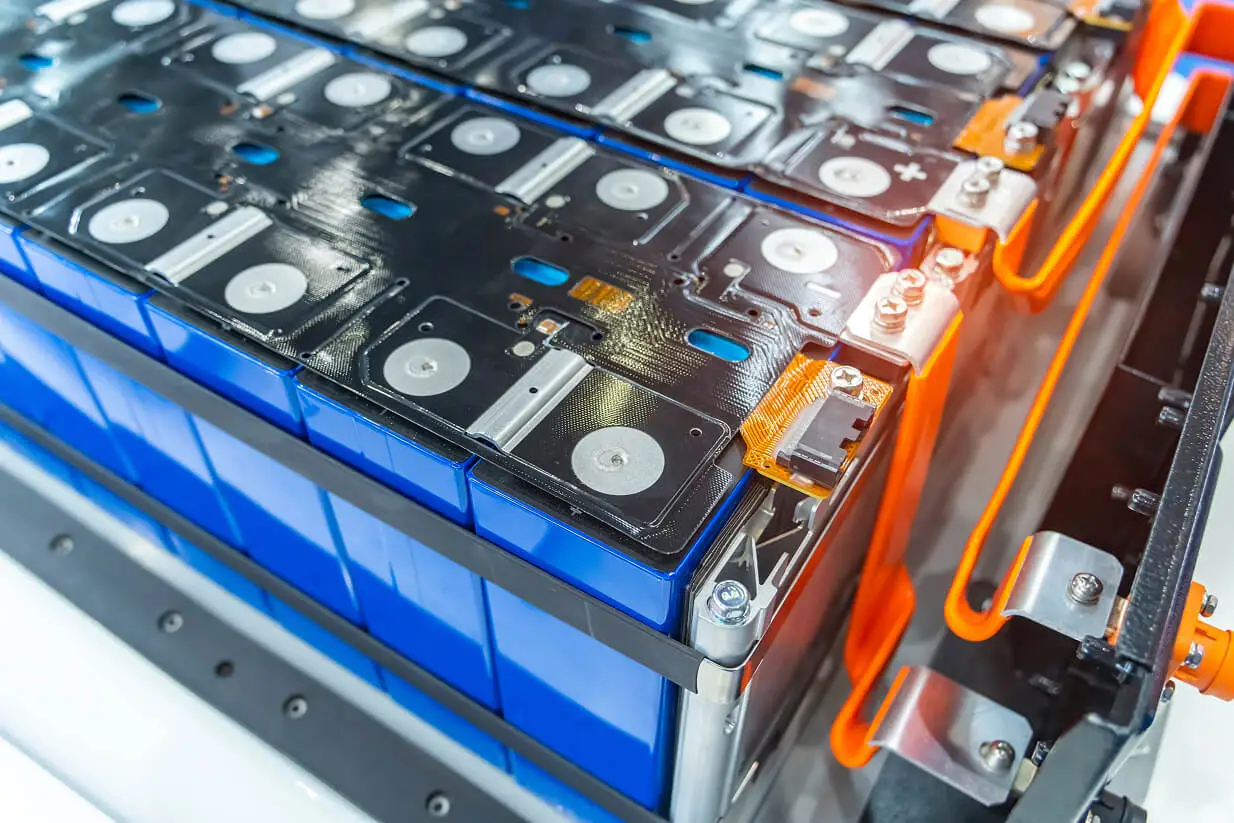

Precise diagnostics form the core of effective lifecycle management for any industrial battery, and Renewance uses proven inspection and testing methods to determine overall health and performance. Our specialists perform cell balancing checks, evaluate state-of-health data, and review electrical integrity through resistance and voltage testing. Each battery undergoes detailed data analysis collected through CAN-based tools that help identify early performance issues long before they affect operations.

Depending on customer requirements, diagnostics may be completed in the field or in a controlled lab environment to capture the most reliable results. These assessments also guide ongoing industrial battery maintenance programs that help extend service life and support safe, predictable operation.

With clear, data-driven evaluations, organizations gain a complete picture of battery condition and the insights needed to effectively plan next steps.